Electronic Manufacturing Services

Introduction

Electronic Manufacturing Services (EMS) is a broad term for services provided by companies that design, produce, test, and distribute electronic parts and assemblies to Original Equipment Manufacturers (OEMs). EMS services are a key component of the development and large-scale production of electronic products used by industries such as consumer electronics, automotive, healthcare, aerospace, and telecommunications. By outsourcing production to EMS providers, OEMs are able to reduce overhead, scale up rapidly, and focus more on core business activities like innovation, marketing, and customer support. This guide takes a close look at EMS — what it is, its major benefits, challenges, industry trends, and its growing global significance.

What Are Electronic Manufacturing Services?

Electronic Manufacturing Services offer a range of services enabling firms to bring electronic products to market efficiently. EMS providers handle the behind-the-scenes activities required to make product development, manufacturing, and distribution convenient. These services typically include:

1. Design and Engineering Services

EMS firms typically support the design process, delivering:

- Product development

- Design for manufacturability (DFM)

- Design for testability (DFT)

- Prototyping and validation

By being involved in the design process at an early stage, EMS providers can reduce costs, improve performance, and shorten time-to-market.

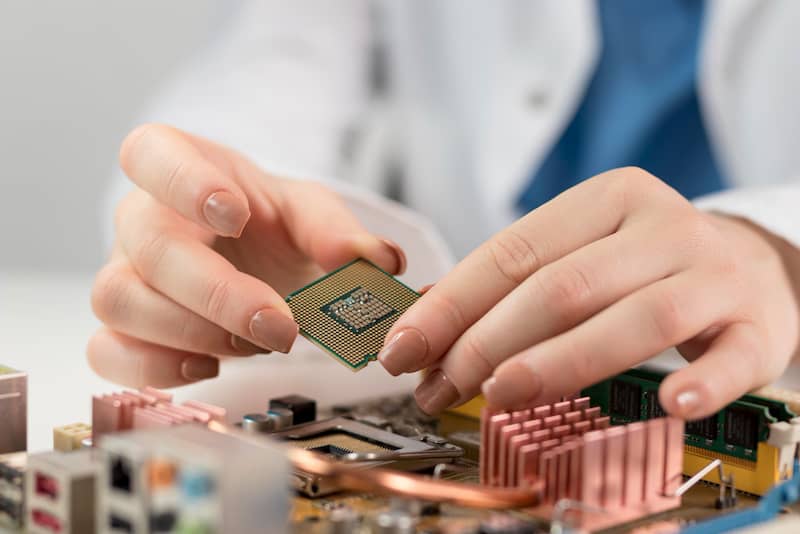

2. PCB Assembly (PCBA)

One of the core EMS operations, where the PCBs are loaded with components either by surface-mount technology or through-hole technology. Soldering, cleaning, and visual inspection come before assembly.

3. Component Sourcing and Procurement

EMS providers are responsible for purchasing components, quality, and price. Electronic Manufacturing Services They have established supplier relationships, so they are in a good position to access high-quality material even during supply chain disruptions.

4. Testing and Quality Control

In order to ensure reliability, EMS companies perform a number of tests such as:

- Functional testing

- In-circuit testing (ICT)

- Burn-in testing

- Environmental stress screening

Testing is crucial in fault detection early in life and product consistency.

5. Box Build and Final Assembly

In addition to circuit boards, EMS companies usually undertake extensive system integration and include enclosures, displays, cables, and connectors.

6. Logistics and Distribution

Modern EMS companies are now offering warehousing, inventory management, and drop-shipping options that allow OEMs to lower handling costs and improve delivery times.

7. Aftermarket and Repair Services

Post product sale support encompasses warranty repair, replacement, and upgrade services that guarantee customer satisfaction in the long term.

Benefits of EMS to OEMs

EMS alliances provide OEMs of all sizes with numerous advantages:

1. Cost-Effectiveness

By employing EMS providers, OEMs avoid heavy capital expenditures in equipment, infrastructure, and manpower. Electronic Manufacturing Services Economies on material purchasing by EMS companies often amount to bulk purchasing.

2. Shorter Time-to-Market

EMS companies streamline the production and development process of products with technical expertise and scalability of processes.

3. Entry to High-Tech Competence

EMS providers make capital investments in high-tech manufacturing equipment and test equipment, enabling OEMs to enjoy high-quality production at zero initial investment.

4. Scalability

OEMs can scale up or down production according to market demands because EMS providers’ manufacturing plants are flexible.

5. Focus on Core Competencies

By having production and logistics outsourced, OEMs can focus more on research, product development, brand building, and customer engagement.

Industries Adopting EMS

1. Consumer Electronics

Smartphones, tablets, TVs, wearables, and gaming consoles are typically manufactured by EMS partners due to volume and complexity.

2. Automotive Electronics

New vehicles use multiple electronic systems, including infotainment, ADAS (Advanced Driver Assistance Systems), and powertrain control. EMS providers help OEMs meet high automotive quality requirements.

3. Healthcare and Medical Devices

Medical electronics such as diagnostic gear, wearable health, and imaging equipment require precise manufacturing and compliance with regulation — a critical EMS specialized knowledge.

4. Industrial Electronics

EMS companies provide automation, robotics, and energy management market with durable and custom-built electronic solutions.

5. Telecommunications

Routers, base stations, and 5G infrastructure components are often produced by EMS companies due to their need for high reliability and rapid time-to-market.

The EMS Lifecycle: From Concept to Delivery

The EMS lifecycle typically follows the following process:

- Concept Development

- Design and Engineering

- Prototype Manufacturing

- Testing and Validation

- Volume Manufacturing

- Logistics and Delivery

- Aftermarket Services

Each phase is strictly managed to deliver reliability, scalability, and performance.

Global EMS Market Overview

The global EMS industry has experienced steady growth due to increasing electronic device penetration, product complexity, and supply chain globalizations.Electronic Manufacturing Services The industry will continue to grow with the following drivers:

- Technological advancement in IoT, AI, and 5G

- Trends in OEM outsourcing

- Demand for miniaturization and multi-functionality in electronic

- products in the marketplace Growing content of electronics in automobiles

- Growth in medical and wearable products

Top regions globally with stable EMS coverage are:

- Asia-Pacific: Leader nations are China, India, Vietnam, and Malaysia as far as qualified labor and cost advantages are concerned.

- North America: EMS companies within the United States dominate high-mix, low-volume production.

- Europe: Germany, Poland, and the UK are being transformed into EMS centers, mainly automotive and medical sectors.

Emerging Trends in EMS

1. Smart Manufacturing (Industry 4.0)

IoT, robotics, AI, and big data analytics are being integrated by EMS providers into their processes for improving efficiency, reducing downtime, and increasing yield rates.

2. Vertical Integration

Various Electronic Manufacturing Services companies are integrating design and aftermarket functionality into their services, giving OEMs a one-stop-shop solution from concept to shipment to customer.

3. Personalization and Customization

There is growing need for customized electronics, and especially in consumer electronics and industrial automation.Electronic Manufacturing Services Flexible production models are being offered more and more by Electronic Manufacturing Services firms.

4. Environmentally Friendly Manufacturing

Greening is coming into the spotlight. Electronic Manufacturing Services suppliers are emphasizing green processes such as:

- Lead-free soldering

- Electronic waste management

- Energy-efficient lines of production

5. Localization of the Supply

Chain International disruptions have caused a reappraisal of manufacturing and sourcing approaches. Most OEMs are near-shoring or reshoring manufacturing to reduce risks, creating regional EMS growth.

Challenges Confronting EMS Providers

1. Component Shortages

The recent global component shortages of semiconductors have put the EMS ecosystem under extreme pressure. Electronic Manufacturing Services Sourcing models need to be diversified and suppliers established in long-term relationships.

2. Uniform Quality Across Facilities

Since facilities are situated worldwide, it is difficult to maintain uniform quality and standards across facilities. Adoption of real-time monitoring and one quality system is of utmost importance.

3. Intellectual Property (IP)

Protection Protection of IP is specially required if sensitive designs are being shipped to foreign countries. EMS providers need to use stringent data management and legal protection.

4. Conformity with Standards

Conformity with safety, environmental, and industry standards (e.g., RoHS, ISO 13485, IATF 16949) is vital in order to maintain the credibility.

5. Talent Shortage

Recruitment and retaining skilled personnel — from engineers to machine operators — gets progressively tougher, especially in high-tech manufacturing.

EMS in India: A Rising Force

India is quickly developing as a world-class EMS center due to favorable government policies, low-cost labor, and a growing indigenous electronics sector. Programs such as:

- Make in India

- Production Linked Incentive (PLI)

- Electronics Manufacturing Clusters (EMC)

are drawing foreign and localElectronic Manufacturing Services investment. Metropolitan cities such as Noida, Chennai, and Bengaluru are being prepared as electronics production hubs with global and local EMS participants.

Choosing the Right EMS Partner

Having the correct EMS partner can make or break product success. Remember the following imperative points:

1. Track Record and Experience

Seek out the experience of the EMS provider in your market segment as well as their track record on similar-size and complexity products.

2. Technical Ability

Visit their facilities, check on certifications, equipment, and engineering resources to ensure that they are able to provide what your product needs.

3. Geographical Proximity

Think about the proximity to your design team, end-users, and suppliers. Logistics and time zones come into play.

4. Supply Chain Network

Make sure their connections with component vendors and logistics vendors to avoid supply chain risk.

5. Quality Assurance

Make sure certifications (e.g., ISO, IATF, etc.) and good quality control processes.

6. Scalability and Flexibility

Your EMS partner must have the capability to scale up/down depending on demand in the market and match the life cycle of your product, beginning from a prototype to mass production.

The Future of EMS

The future of Electronic Manufacturing Services is radical and optimistic. With digital transformation accelerating, EMS providers will be at the forefront of making innovation happen, product excellence, and intricate global supply chain management.

Near-future advancements will probably comprise:

- More AI applications on the production lines

- More use of digital twins for simulation and testing

- More OEM-EMS consolidation

- More localization of EMS to cushion against geopolitical risk

Conclusion

Electronic Manufacturing Services are the key to the new electronics business. From hospital equipment to cell phones, EMS suppliers allow OEMs to design, produce, and deliver products at velocity and precision.

As the electronics business competes more aggressively and becomes more complicated, business success can be influenced by the selection of an appropriate EMS provider. Electronic Manufacturing Services By defining EMS capabilities, intentional provider selections, and keeping up to date with industry innovation, OEMs can achieve a winning edge in their markets.

Whether introducing a new Internet-of-Things product or ramping automotive systems production, Electronic Manufacturing Services offer the infrastructure, intelligence, and scalability to drive your growth path.more